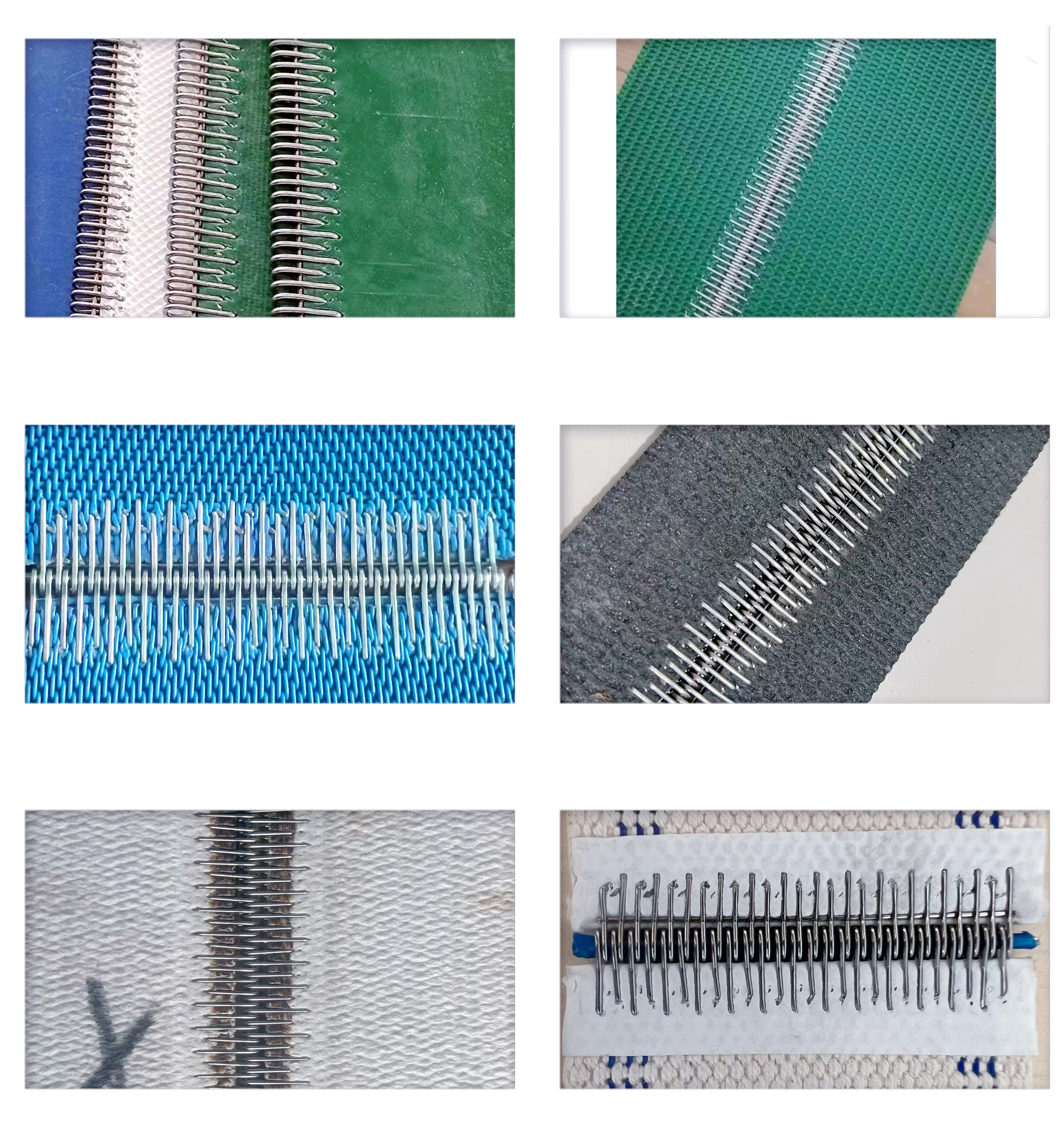

Understanding Belt Fasteners and Their Role in Industry

Belt fasteners serve as critical components in various industrial applications, ensuring the effective and reliable connection of conveyor belts. As industries evolve, the demand for durable, efficient belt fasteners has surged. A reputable belt fasteners manufacturer knows how to meet these needs through innovative solutions and quality materials. By focusing on the specific attributes of belt fasteners, manufacturers can significantly enhance operational performance and efficiency. For example, a factory utilizing the wrong type of fastener may encounter frequent breakdowns, leading to costly downtime and maintenance expenses. Therefore, selecting a knowledgeable manufacturer plays a pivotal role in sustaining production workflows and optimizing equipment longevity.

Benefits of Partnering with a Leading Belt Fastener Supplier

Collaborating with a well-established belt fastener supplier can offer myriad advantages for businesses. Firstly, these suppliers typically have a wealth of experience and industry knowledge, allowing them to recommend suitable fasteners tailored to specific applications. For instance, if a business operates in a high-temperature environment, a supplier can guide the selection of heat-resistant fasteners. Furthermore, a distinguished supplier often provides comprehensive customer service, assisting with installation and maintenance advice that empowers clients to maximize their operational efficiency. Building a strong relationship with a supplier also facilitates access to new technologies and innovations, keeping businesses competitive in an ever-changing marketplace.

The Value of Choosing a Reliable Conveyor Belt Fasteners Manufacturer

The selection of a trustworthy conveyor belt fasteners manufacturer is vital for the seamless functioning of various industrial processes. With the right manufacturer, businesses can obtain fasteners that not only promise durability but also enhance overall productivity. For instance, if a manufacturer employs advanced materials and techniques, the resulting fasteners can withstand higher stress, reducing the frequency of replacements. Additionally, a reputable manufacturer is likely to adhere to stringent quality control standards, ensuring that every batch of fasteners meets precise specifications. This attention to detail can significantly mitigate the risks associated with equipment failure and operational downtime, ultimately contributing to a smoother, more reliable production line.

Conclusion: Why Choose Intake as Your Preferred Manufacturer

In summary, opting for a professional and experienced manufacturer for your belt fasteners needs can drastically impact your operational efficiency and productivity. With a strong emphasis on quality and customer service, Intake stands out in the industry. Their commitment to providing durable and reliable solutions means clients can trust that their equipment will perform at optimal levels without frequent interruptions. Additionally, Intake’s focus on innovation ensures that businesses receive cutting-edge products that meet evolving industrial demands. Ultimately, selecting Intake as your manufacturer not only strengthens supply chains but also enhances the overall reliability of your operations.

Expanding on Practical Benefits of a Belt Fasteners Supplier

Engaging with a professional belt fastener supplier extends beyond transactional relationships; it forms a strategic alliance that drives growth and innovation. Suppliers with extensive industry experience offer insights that can help businesses avoid common pitfalls in the selection and application of fasteners. For example, an expert supplier would ensure that businesses consider environmental factors, such as humidity and temperature, which may influence their choice of materials. This proactive approach in consultation often results in increased product lifespan and operational efficiency, saving costs in the long run. Furthermore, many suppliers also provide warranties or guarantees, adding an additional layer of security and confidence in their products. As a result, partnering with a knowledgeable supplier can foster an environment where businesses are more agile, responsive, and ultimately successful.

Diving Deeper into Conveyor Belt Fastener Choices

When selecting a conveyor belt fasteners manufacturer, it is essential to consider both the technical specifications and the manufacturer’s reputation for quality. Fasteners come in various types, such as mechanical or chemical, each suited for different applications. For example, mechanical fasteners are often favored for their ease of installation and removal, making them ideal for maintenance-heavy operations. Conversely, chemical fasteners may offer superior strength for permanent applications. A reliable manufacturer not only provides a range of options but also educates clients on selecting the right type for their specific operational demands. This guidance can prevent costly mistakes and ensure that businesses select fasteners that optimize performance and minimize downtime.